25 years of non-woven production and export experience.

A number of high-quality suppliers of large luggage brands.

Strictly passed ISO9001, GRS, SGS and other certifications.

The company has five warehouses overseas.

Related Products

More items about spunbond nonwoven fabric

We Have The Best Solutions for Your Business

Since 1997, the company has focused on the production of nonwoven products, mainly engaged in pp spunbond nonwoven fabrics, meltblown nonwoven fabrics, sms nonwoven fabrics, pe laminated nonwoven fabrics, spunlace nonwoven fabrics, pet nonwoven and other nonwoven fabrics. We have two production parks of more than 100 acres, with branches in Hong Kong, Vietnam, the Philippines, Myanmar, Indonesia and other places. The Group's non-woven products have established long-term friendly cooperative relations with world-renowned luggage, handbags and footwear brands and factories such as Coach, Michael Kors, Kate Spade, Tory Burch, Calvin Klein, Chanel, Prada, Under Armour, Dissona, etc. The products have passed ISO9001, ISO13485, GRS quality certification and EU SGS, ROHS, REACH and other environmental testing.

Importance of Spunbond Nonwoven Fabrics

Spunbond nonwoven fabric have a high tear strength, thus making them more resilient than any other type of material.

The fabric is layered, which makes it more durable.

polypropylene unwoven fabric is highly repellant to liquids and thus has high tensile strength and flexibility.

The fast manufacturing method makes them affordable for people to consume for miscellaneous purposes.

spunbond fabrics have excellent physical properties that make them an appropriate pick.

How to choose spunbond non-woven fabrics?

1. First determine the purpose of purchasing non-woven fabrics.

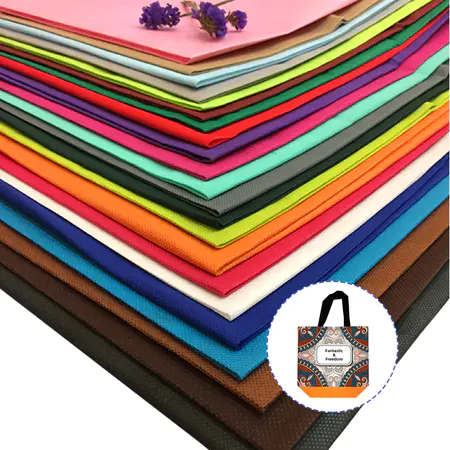

2. Determine the color of the non-woven fabric.

3. Determine the gram weight and door width.

4. Determine the quality of the non-woven fabric.

What are the specific applications of spunbond non-woven fabrics?

1. Spunbond non-woven fabrics can be widely used in shopping bags, gift bags, handbags, information bags, carpets and base fabrics, wall materials, furniture decoration, dust-proof cloth, spring wrapping cloth, isolation cloth, audio cloth, bed Supplies and curtains, rags and other household daily necessities industry.

2. Spunbond non-woven fabrics can be widely used in clinical supplies, surgical gowns, hats, shoe covers, bandages, bandages, wet towels, cotton balls, masks, sterilization cloths, sanitary napkins, diapers, vacuum bags, travel underwear, Incontinence products, wet and dry wipes, cosmetic paper, sanitary materials and other medical and health industries.

3. It can be widely used in car carpets, roofs, door trims, composite materials, seat materials, wall protection materials, etc.

4. It can be widely used in agricultural and horticultural industries such as thermal insulation coverage, frost protection, insect control, lawn protection, plant mulch, seedling cloth, soilless cultivation, artificial vegetation and so on.

5. Spunbond non-woven fabrics can be widely used in coating cloths, polishing materials, wiping cloths, sterile clothing, abrasive products, cable wrapping cloths, battery separators, tapes, protective clothing, lab coats, flame retardant cloths, conveyor belts , Use disposable felt, papermaking felt, sound-absorbing felt and other industrial aspects.

Applications of Spunbond Nonwovens

Various industries utilize spunbond nonwoven fabric for disposal purposes like masks, sanitary napkins, bandages, towels, wipes, child diapers, disposable dresses, carry bags, dust cloths, etc.

The dewatering property of the fabric allows it to be used widely for the closing of cement and concrete.

As the nonwovens are highly durable, they also have significant use in the production of household goods and home furnishing products like drapes, upholstery, mattress paddings, table covers, chair covers, carpets, etc.

In addition to that, the fabric is also required for the making of tea bags, filtering products, gel bags, and other similar products.

Frequently Asked Question

Do you have any question?

Nonwoven fabrics made by spun bond process are being used in various applications like disposable diapers, hygiene and healthcare textiles, filtration, automotive industry, civil engineering, packaging, carpet backings.

We need the following information from you: 1.spunbond nonwoven fabric specifications: width, length, weight (gsm), color 2.The use of spunbond nonwoven fabric

S is spunbond nonwoven, single S is single-layer spunbond nonwoven, double S is double-layer composite spunbond nonwoven, and triple S is three-layer composite spunbond nonwoven.

.jpg?imageView2/1/w/450/h/450/format/webp)